AVR单片机控制的电动自行车驱动系统程序

2012-10-28

标签:

AVR

#include < avr / io.h >

//电动自行车双闭环程序,采用双闭环方式控制电机,以得到最好的转速性能,并且可以

//限制电机的最大电流。本应用程序用到两个CCP部件,其中CCP1用于PWM输出,以控

//制电机电压;CCP2用于触发AD,定时器TMR2、TMR1,INT中断,RB口电平变化中断,

//看门狗以及6个通用I/O口

#define AND0xe0//状态采集5,6,7位

#define CURA 0X0a//电流环比例和积分系数之和

#define CURB 0X09//电流环比例系数

#define THL0X6400//电流环最大输出

#define FULLDUTY 0X0FF//占空比为1时的高电平时间

#define SPEA 0X1d//转速环比例和积分系数之和

#define SPEB 0X1c//转速环比例系数

#define GCURHILO 0X0330//转速环最大输出

#define GCURH 0X33//最大给定电流

#define GSPEH 0X67//最大转速给定

#define TSON 0X38//手柄开启电压1.1 V,TSON*2为刹车后手柄开启电压,即

//2.2 V

#define VOLON 0X4c//低电压保护重开电压3.0 V即33 V

#define VOLOFF 0X49//低电压保护关断电压2.86 V即31.5 V

volatile unsigned char DELAYH, DELAYL, oldstate, speed,

speedcount, tsh, count_ts, count_vol, gcur, currenth,

voltage;//寄存器定义

static bit sp1, spe, ts, volflag, spepid, lowpower,

off, shutdown, curpid; //标志位定义

static volatile unsigned char new[10] = {0xaf, 0xbe, 0xff, 0x7e, 0xcf,

0xff, 0xd7, 0x77, 0xff, 0xff

};//状态寄存器表

//------------PIC16F877初始化子程序------------

void INIT877()

{

PORTC = 0X0FF; //关断所有MOSFET

TRISC = 0X02; //设置C口输出

PIE1 = 0X00; //中断寄存器初始化,关断所有中断

TRISA = 0XCF; //设置RA4,RA5 输出

TRISB = 0XEF; //RB 口高三位输入,采集电机三相的霍尔信号

PORTC = new[(PORTB & AND) >> 5]; //采集第一次霍尔信号,并输出相应的信号,导通

//两个MOS管

T2CON = 0X01; //TMR2 4分频

CCPR1L = 0X0FF; //初始时PWM输出全高

CCP1CON = 0X0FF; //CCP1设置为PWM方式

CCP2CON = 0X0B; //CCP2设置为特殊方式,以触发AD

ADCON0 = 0X81; //AD时钟为32分频,且AD使能,选择AN0通道采集手

//柄电压

TMR2 = 0X00; //TMR2寄存器初始化

TMR1H = 0X00; //TMR1寄存器初始化

TMR1L = 0X00;

T1CON = 0X00; //TMR1为

CCPR2H = 0X08;

CCPR2L = 0X00; //电流采样周期设置为TAD=512 μs

PR2 = 0XC7; //PWM频率设置为5 kHz

ADCON1 = 0X02; //AD结果左移

OPTION = 0XFB; //INT上升沿触发

TMR2ON = 1; //PWM开始工作

INTCON = 0XD8; //中断设置GIE=1,PEIE=1,RBIE=1

ADIE = 1; //AD中断使能

speedcount = 0x00; //转速计数寄存器

speed = 0x7f; //转速保持寄存器

spe = 1; //低速标志位

sp1 = 1; //低速标志位

oldstate = 0x0ff; //初始状态设置,区别于其他状态

count_ts = 0x08; //电流采样8次,采集1次手柄

count_vol = 0x00; //采样256次手柄,采集1次电池电压

ts = 1; //可以采集手柄值的标志位

ADGO = 1; //AD采样使能

TMR1ON = 1; //CCP2部件开始工作

}

//------------延时子程序---------------

#pragma interrupt_level 1

void DELAY1(x)

char x;

{

DELAYH = x; //延时参数设置

#asm

DELAY2 MOVLW 0X06

MOVWF _DELAYL

DELAY1 DECFSZ _DELAYL

GOTO DELAY1

DECFSZ _DELAYH

GOTO DELAY2

#endasm

}

//-----------状态采集子程序----------------------

void sample()

{

char state1, state2, state3, x;

do {

x = 1;

state1 = (PORTB & AND); //霍尔信号采集

DELAY1(x);

state2 = (PORTB & AND);

}

while (state1 - state2); //当三次采样结果不相同时继续采集状态

if (state1 - oldstate != 0) //看本次采样结果是否与上次相同,不同

//则执行

{

oldstate = state1; //将本次状态设置为旧状态

state1 = (oldstate >> 5);

PORTC = new[state1]; //C口输出相应的信号触发两个MOS管

if (sp1 == 1) {

spe = 1;

sp1 = 0;

}

else {//如果转速很低,则spe置1

spe = 0;

sp1 = 0;

speedcount <<= 1;

state3 = (TMR1H >> 2); //否则,spe=0,计转速

speed = speedcount + state3; //speed寄存器为每256 μs加1

}

speedcount = 0;

}

}

//-----------------AD采样子程序----------------------

void AD()

{

char x;

ADIF = 0; //清AD中断标志位

if (ts == 1) { //如果为手柄采样,则采样手柄值

CHS0 = 1; //选择电流采样通道

count_vol = count_vol + 1; //电池采样计数寄存器

spepid = 1; //置转速闭环运算标志

ts = 0;

tsh = ADRESH; //存手柄值

if (count_vol == 0) { //如果电池采样时间到,则选择AN2通道,采集电池电压

CHS0 = 0;

CHS1 = 1;

volflag = 1;

x = 1;

DELAY1(x);

ADGO = 1;

}

}

else if (volflag == 1) { //电池采样完毕,进行相应的处理

CHS1 = 0;

CHS0 = 1;

volflag = 0;

voltage = ADRESH;

lowpower = 1;

}

else {

//否则,中断为采样电流中断

speedcount = speedcount + 1; //speedcount寄存器加1,作为测量转速用

if (speedcount > 0x3d) {

sp1 = 1; //如果转速低于1 000 000 μs/(512 μs*3eh*3)

}

// 则认为为低速状态

currenth = ADRESH;

curpid = 1;

count_ts = count_ts - 1;

if (count_ts == 0) { //如果手柄时间到,则转入手柄采样通道

CHS0 = 0;

count_ts = 0x08;

ts = 1;

x = 1;

DELAY1(x);

ADGO = 1;

}

}

}

//-------------刹车处理子程序------------------

void BREAKON()

{

char x;

off = 0; //off清零,如果是干扰则不复位

shutdown = 0;

if (RB0 == 1) { //如果刹车信号为真,则停止输出电压

ADIE = 0; //关AD中断

INTE = 0; //关刹车中断

CCPR1L = FULLDUTY; //输出电压0

TMR1ON = 0; //关CCP2,不再触发AD

for (; ADGO == 1;) {

continue; //如正在采样,则等待采样结束

}

ADIF = 0; //ADIF位清零

CHS0 = 0; //选择通道0采样手柄

CHS1 = 0;

x = 1;

DELAY1(x);

do {

ADGO = 1;

for (; ADIF == 0;) {

continue;

}

ADIF = 0;

CCPR1L = FULLDUTY;

asm("CLRWDT");

tsh = (ADRESH >> 1);

}

while (tsh > TSON || RB0 == 1); //当手柄值大于2.2 V或刹车仍旧继续时,执行以

//上语句

off = 1; //置复位标志

}

}

//---------欠保护子程序-------------------

void POWER()

{

char x;

lowpower = 0;

voltage >>= 1; //电压值换为7位,以利于单字节运算

if (voltageADIE = 0;

INTE = 0;

TMR1ON = 0;

CCPR1L = FULLDUTY;

for (; ADGO == 1;)continue;

ADIF = 0;

CHS0 = 0; CHS1 = 1;

x = 1;

DELAY1(x);

do {

ADGO = 1;

for (; ADIF == 0;) {

continue;

}

ADIF = 0;

voltage = (ADRESH >> 1);

CCPR1L = FULLDUTY;

asm("CLRWDT");

}

while (voltageoff = 1; //置复位标志

}

}

//------------电流环运算子程序-----------------

void CURPI()

{

static int curep = 0x00, curek = 0x00, curuk = 0x00;

union data {

int pwm;

char a[2];

} b; //定义电流环运算寄存器

curpid = 0; //清电流运算标志

curep = curek * CURB; //计算上一次偏差与比例系数的积

if (currenth < 2) {

currenth = 2; //如果采样电流为零,则认为有一个小电

}

流以利于

//使转速下降

currenth >>= 1;

curek = gcur - currenth; //计算本次偏差

curuk = curuk + curek * CURA - curep; //按闭环PI运算方式得到本次输出结果,

下

//面对结果进行处理

if (curuk < 0x00) { //如果输出小于零,则认为输出为零

curuk = 0;

CCPR1L = FULLDUTY;

CCP1X = 0;

CCP1Y = 0;

}

else if (curuk - THL >= 0) {

//如果输出大于限幅值,则输出最大电压

curuk = THL;

CCPR1L = 0;

CCP1X = 0;

CCP1Y = 0;

}

else { //否则,按比例输出相应的高电平时间到CCPR1寄存器

b.pwm = THL - curuk;

b.pwm <<= 1;

CCPR1L = b.a[1]; //CCPR1L=(b.pwm>>8)&0x0ff;将PWM寄存器的高半字节

if (b.pwm & 0x80 != 0) {

CCP1X = 1;

}

else {

CCP1X = 0;

}

if (b.pwm & 0x40 != 0) {

CCP1Y = 1;

}

else {

CCP1Y = 0;

}

}

}

//---------------转速环运算子程序-----------------------

void SPEPI()

{

static int speep = 0x00, speek = 0x00, speuk = 0x00;

int tsh1, speed1; //转速寄存器定义

spepid = 0; //清转速运算标志

if (spe == 1) {

speed1 = 0x00; //若转速太低,则认为转速为零

}

else {

speed1 = 0x7f - speed; //否则计算实际转速

}

if (speed1 < 0) {

speed1 = 0;

}

speep = speek * SPEB;

tsh1 = tsh - 0x38; //得到计算用的手柄值

speek = tsh1 - speed1;

if (tsh1 < 0) {

speuk = 0; //当手柄值低于1.1 V时,则认为手柄给定为零

gcur = 0;

}

else { //否则,计算相应的转速环输出

if (tsh1 >= GSPEH) { //限制最大转速

tsh1 = GSPEH;

}

speuk = speuk + speek * SPEA - speep; //计算得转速环输出

if (speuk <= 0X00) {

speuk = 0x00; //转速环输出处理

gcur = 0x00;

}

else if (speuk > GCURHILO) { //转速环输出限制,即限制最大电流约12

A

speuk = GCURHILO;

gcur = GCURH;

}

else { //调速状态时的输出

gcur = (speuk >> 4) & 0x0ff;

}

}

}

//-----------主程序-------------------------

main()

{

for (;;) {

INIT877(); //单片机复位后,先对其进行初始化

off = 0; //清复位标志

for (; off == 0;) { //复位标志为零,则执行下面程序,否则复位

if (curpid == 1) {

CURPI(); //电流PI运算

}

else if (spepid == 1) {

SPEPI(); //转速PI运算

}

else if (lowpower == 1) {

POWER();

}

else if (shutdown == 1) {

BREAKON();

}

asm("CLRWDT");

}

}

}

//---------中断服务子程序---------------------

#pragma interrupt_level 1

void interrupt INTS(void)

{

if (RBIF == 1) {

RBIF = 0;

sample();

}

else if (ADIF == 1) {

AD();

}

else if (INTF == 1) {

shutdown = 1; //刹车中断来,置刹车标志

INTF = 0;

}

}

可能会用到的工具/仪表

相关文章

推荐文章

-

热敏电阻温度阻值查询程序2024年11月13日 74

-

C99语法规则2024年11月16日 675

-

FreeRTOS 动态内存管理2024年11月12日 448

-

一款常用buffer程序2024年11月06日 88

-

1602液晶显示模块的应用2012年08月03日 191

-

GNU C 9条扩展语法2024年11月18日 261

-

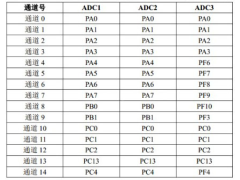

如何实现STM32F407单片机的ADC转换2024年11月15日 300

-

STM32使用中断屏蔽寄存器BASEPRI保护临界段2024年11月15日 195

热门文章

-

C99语法规则2024年11月16日 675

-

51单片机LED16*16点阵滚动显示2012年09月05日 664

-

FreeRTOS 动态内存管理2024年11月12日 448

-

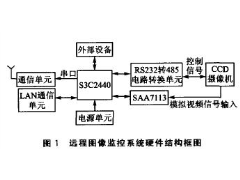

ARM9远程图像无线监控系统2012年07月03日 424

-

用单片机模拟2272软件解码2012年09月06日 300

-

如何实现STM32F407单片机的ADC转换2024年11月15日 300

-

新颖的单片机LED钟2012年08月06日 278

-

GNU C 9条扩展语法2024年11月18日 261

章节目录